|

Orthonex Technology:

Tensile Control Rod

Introduction

to Orthonex's Tensile Control Rod for Dynamic Stabilization

Orthonex's patent pending

"Tensile Control Rod" is an innovative device for dynamic stabilization

of the spine. The Tensile Control Rod is a longitudinal implantable

device for dynamic stabilization of the spine that is attached posteriorly

to the spine in a manner similar to attachment of a conventional spinal

rod. However, unlike a conventional spinal rod, the Tensile Control

Rod allows desirable spinal movement and prevents undesirable spinal movement.

Further, the Tensile Control Rod enables adjustment of the range and dampening

of spinal motion in different directions, including the possibility of

adjustments during surgery and also non-invasively (via wireless control)

after surgery.

How

Does Orthonex's Tensile Control Rod Work?

The Tensile Control Rod includes

the following components: (1) a longitudinal sequence of incompressible

segments that connect spinal vertebrae, contain non-central longitudinal

channels, and provide spinal support; (2) substantially-inelastic members

(e.g. tensile wires) that run through these non-central channels, connect

the incompressible segments, and restrict spinal movement so that it remains

within a desirable range of motion; and (3) motion-dampening members (e.g.

springs) that also run through the non-central channels and advantageously-dampen

spinal movement within the desirable range of motion.

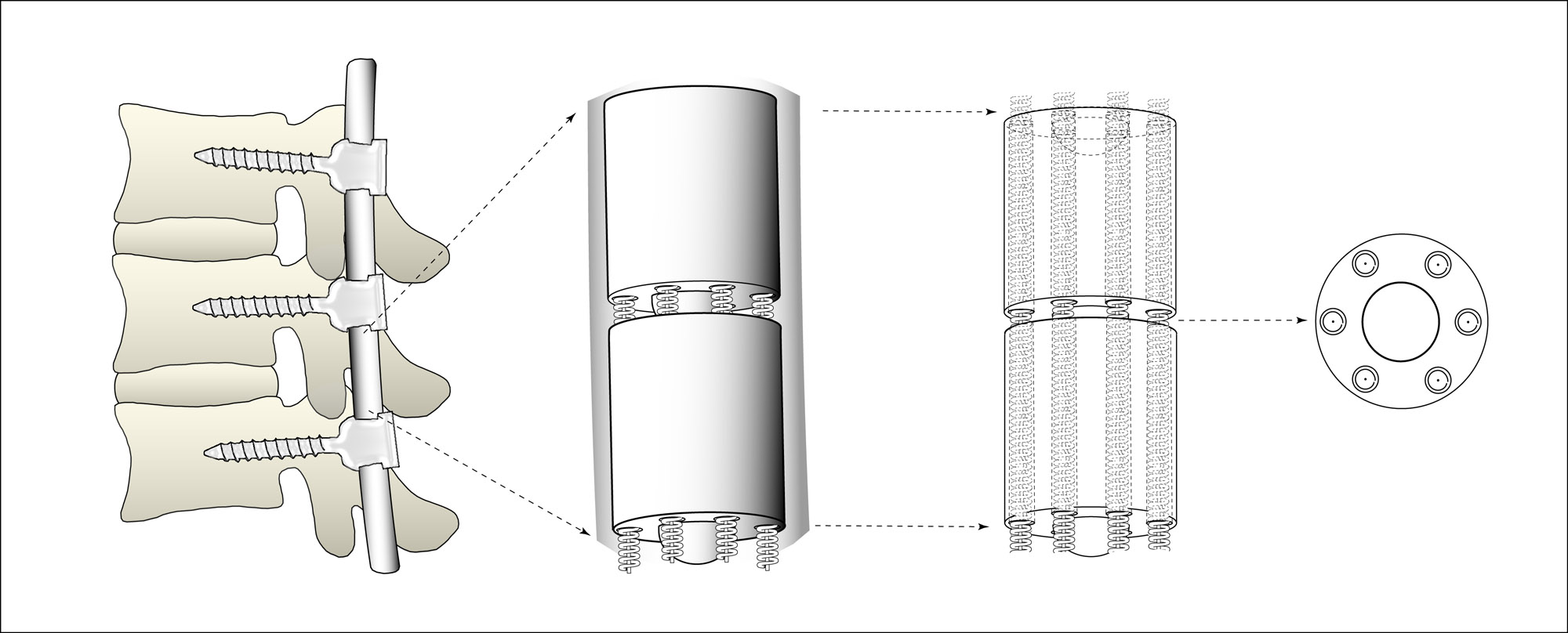

Figure 1 shows one example

of how Orthonex's Tensile Control Rod may be designed to provide dynamic

stabilization of the spine. The far-left portion of Figure 1 shows

the exterior of a rod-like version of this device that has been posteriorly

attached, with pedicle screws, to a sequence of spinal vertebrae.

The mid-left portion of Figure 1 shows a close-up, primarily-opaque, side

view of two of the cylindrical segments that are part of a longitudinal

sequence of multiple cylindrical segments forming the interior of the Tensile

Control Rod.

Figure 1: Orthonex's

Tensile Control Rod

(different views, before

flexion)

In the mid-left portion of

Figure 1, the upper cylindrical segment is shown with six channels that

run longitudinally through the cylinder and intersect its cross-section

in a roughly circular manner. Since the mid-left portion is

a primarily-opaque view of the segments, the channels are only visible

where they open onto the bottom end portion of the upper cylindrical segment.

Two of the six channels do not appear in this view because they are obscured

by a partial ball-like protrusion that protrudes from the bottom end portion

of the upper cylindrical segment. This ball-like protrusion fits

into a socket in the top end portion of the lower cylindrical segment.

This ball-like protrusion and socket comprise a partial ball-and-socket

joint between the upper segment and the lower segment. In this example,

within each of the longitudinal channels, there is a coaxial set of longitudinal

members including a longitudinal spring and a longitudinal wire inside

the spring. These springs and wires run longitudinally through the

upper and lower cylindrical segments and connect these segments to each

other.

The mid-right portion of

Figure 1 shows a partially-transparent side view of the same two cylindrical

segments. This portion shows interior transparent views of four of

the six longitudinal channels, each including a longitudinal spring with

a wire running longitudinally through its center. If this figure

were fully transparent, then the rear two channels would also be shown.

However, such full transparency would clutter the figure too much, so the

rear two channels are not shown. This is why this figure is called

a partially transparent, rather than a fully transparent, side view.

In this example, there is some slack in all of the connecting wires when

the spine is in a baseline configuration with minimal longitudinal extension,

tilting, and rotation. This baseline configuration is represented

by the longitudinal alignment of the two cylindrical segments. The

far-right portion of Figure 1 provides a cross-sectional view of the bottom

of the top cylinder, showing the six channels, cross-sections of the springs

with wires inside, and the ball portion of the ball-and-socket joint connecting

the two cylinders.

In this example of the Tensile

Control Rod, the rigidity of the two cylindrical segments, connected by

a partial ball-and-socket joint, resists longitudinal compression of the

spine, but allows some degree of tilting, rotation, and longitudinal extension

of the spine. The inelasticity of the connecting wires limits the

degree of tilting, rotation, and longitudinal extension to a desirable

range of motion. The force resistance of the connecting springs dampens

movement of the spine within this allowable range of motion. Acting

together, these components provide dynamic stabilization of the spine.

They advantageously allow dampened movement within a desired range of motion

and prevent movement outside this desired range of motion.

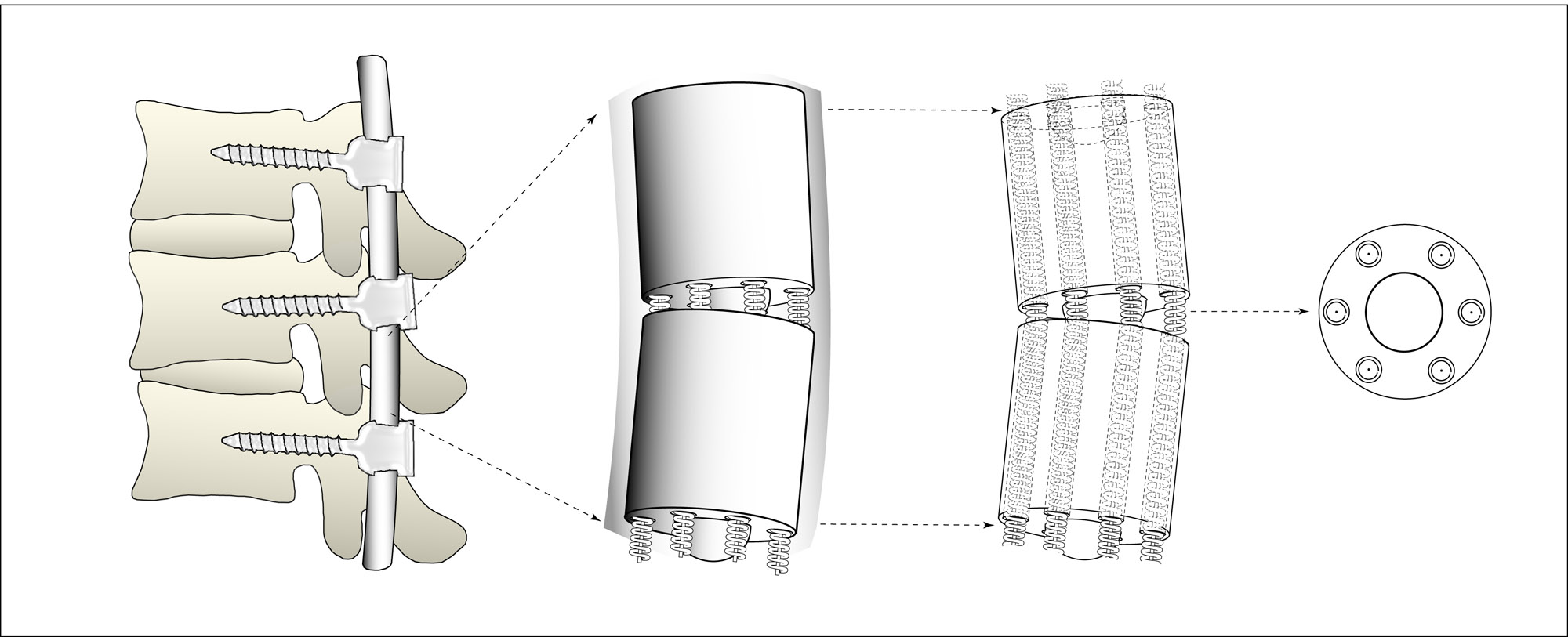

Figure 2 shows how the Tensile

Control Rod moves when the spine flexes and the cylindrical segments are

tilted relative to each other. The slack in different wires increases

or decreases when the spine tilts. When slack in a wire decreases

to zero from this tilting motion, then the wire becomes taut and prevents

further movement in that direction. This is how the substantially-inelastic

members, embodied by wires in this example, prevent undesirable movement

of spinal vertebrae relative to each other.

Figure 2: Orthonex's

Tensile Control Rod

(different views, after

flexion)

In Figure 2, the cylindrical

segments have been tilted relative to each other by movement of the spine.

In this example, wires on the right side of the segments have been pulled

taut by the tilting movement while wires on the left side of the segments

have become more slack. At some point, the tautness of the wires

on the right side prevents further tilting of the segments in this direction.

This is how the substantially-inelastic longitudinal members connecting

the segments, wires in this example, prevent undesirable motion of the

vertebrae relative to each other.

The tilting of the segments

in Figure 2 does not affect only the degree of slack in different wires.

This tilting also affects the extension of different springs. For

example, left-ward tilting in this example causes springs on the right

side of the segments to become more extended and the springs on the left

side of the segments to become more compressed. This is how the motion-dampening

longitudinal members, springs in this example, provide advantageous dampening

of vertebral motion within the range of motion allowed by the substantially-inelastic

members.

The relative slack or tension

of each of the tensile members (wires in this example) may be adjusted

during surgery to achieve the desired range and dampening of spinal movement.

This may include spinal distraction for gradual correction of scoliosis

or other spinal deformity. The tensile members may also be wirelessly

and non-invasively adjusted in the weeks, months, or even years after surgery

by remote communication with an implantable actuator or based on automatic

interaction between implanted sensors and the actuator. In this respect,

Orthonex's Tensile Control Rod can be one of the first "smart devices"

for dynamic stabilization of the spine, allowing non-invasive adjustment

of the range and dampening of spinal movement after surgery.

Potential

Advantages Over Current Devices and Methods for Dynamic Stabilization of

the Spine

Orthonex's Tensile Control

Rod addresses many of the limitations of current devices and methods for

dynamic stabilization of the spine.

In contrast to methods using

flexible elastic members only or flexible inelastic members only, the Tensile

Control Rod provides good support for the spinal column, provides selective

control of the degree and range of movement in different directions, and

has potential for adjustment after implantation.

In contrast to methods using

springs or spring-like cut-metal members only, the Tensile Control Rod

provides good support for the spinal column, provides selective control

of the degree or range of movement in different directions, has potential

for adjustment after implantation, and has no flexing metal springs or

spring-like structures that may weaken and break with repeated movement.

In contrast to methods using

flexible members with flexible inelastic members inside or flexible members

inside, the Tensile Control Rod provides good vertical support for the

spinal column, provides selective control of the degree or range of movement

in different directions, and has potential for adjustment after implantation.

In contrast to methods using

flexible members with rigid rods inside, the Tensile Control Rod does not

have flexing (thin) rods that may weaken or break with repeated movement,

does not require an expensive array of parts such as multiple size and

shape rigid inserts, allows natural spine movement in multiple directions

(flexion, extension, lateral bending, and torsion), and has potential for

non-invasive adjustment after implantation.

In contrast to methods using

non-contiguous rigid segments connected by flexible members, the Tensile

Control Rod: provides good vertical support for the spinal column, provides

selective control of the degree or range of movement in different directions;

and has potential for non-invasive adjustment after implantation.

In contrast to methods using

contiguous rigid segments connected by a central flexible member, the Tensile

Control Rod provides good leverage for selective control of the degree

or range of movement in different directions, allows the use rounded of

rounded (e.g. ball-and-socket) joints between rigid segments because there

is no connecting flexible member in the segment center; and has potential

for non-invasive adjustment after implantation.

In contrast to methods using

contiguous rigid segments connected by only one type of non-central flexible

member, the use of both inelastic and motion-dampening longitudinal members

(such as wires and springs) allows: firmer restriction of movement outside

the desired range of motion; and more precise control of motion-dampening

within the desired range of motion.

In contrast to methods using

telescoping members with springs or gears, the Tensile Control Rod allows

natural flexion and lateral bending movement of the spine, is less prone

to mechanical or material failure, and has the potential for non-invasive

adjustment after implantation.

In contrast to methods using

telescoping members with a flowable substance inside that are directly

attached to the vertebrae, the Tensile Control Rod provides selective control

of the degree or range of movement in different directions without weakening

the vertebrae with a large number of holes, and avoids having an irregularly-shaped

moving structure which is difficult to isolate from surrounding body tissue

and liquids.

In contrast to methods using

integrated configurations of differentially-flexible materials, the Tensile

Control Rod provides good vertical support for the spinal column, is less

prone to mechanical or material failure because there are no shearing or

large-scale flexing members, provides selective control of the degree or

range of movement in different directions, and has the potential for non-invasive

adjustment after implantation to refine therapy or accommodate patient

growth.

To summarize, Orthonex's

Tensile Control Rod has many potential advantages over current methods

of dynamic stabilization. It has considerable potential to restore

normal spinal biomechanics and offers new possibilities for adjustment

before and after implantation. It can be a useful addition to the

treatment options available for the millions of people suffering from chronic

lower back pain. |